Why Metal Profile Choice Still Matters

Choosing the right metal panel profile ensures optimal appearance, performance and install efficiency. At first glance, most metal panel profiles might seem similar. They're made of the same material. They're built to last. And yes, many offer comparable strength and weather resistance. But when you zoom in on the details that define a successful build — visual impact, installation efficiency, and functional fit — the profile you choose can make all the difference.

Whether you're designing a modern urban façade, roofing a curved agricultural structure, or building a trailer floor that needs to take a beating, your panel's rib pattern affects more than just appearance. It influences how light and shadow fall, how well the panels stack and install, and how your project performs over time.

This guide breaks down CMI's most-used profiles grouped by category and application, so you can quickly compare what's available, understand the best fit for your needs, and choose with confidence.

What to Consider When Choosing a Profile

Even when structural specs are similar, choosing the right profile can impact both the aesthetics and efficiency of your project. Here are a few key factors to keep in mind:

- Aesthetic tone: Are you going for a bold, industrial look? Something sleek and modern? Or a classic, utilitarian style?

- Rib depth and spacing: These affect how much visual texture the panel provides, especially when viewed from different distances and angles.

- Panel width and coverage: Some profiles cover more surface area per panel, which can affect material efficiency and installation speed.

- Application context: Different environments and uses call for different profiles. A trailer floor has very different requirements than a commercial façade or a farm shed roof.

- Installation requirements: Some profiles offer greater flexibility for curved surfaces or tighter installation spaces.

- Project requirements: Consider the specific needs of your build, whether that's strength, weight, or installation speed.

Thinking through these elements before you spec can help ensure you choose a panel that looks great, performs reliably, and supports your project goals.

CMI Panel Profiles by Category

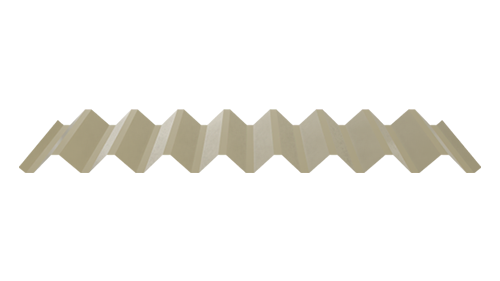

1. Classic Corrugated & Sinewave

This residential building features Sinewave siding panels.

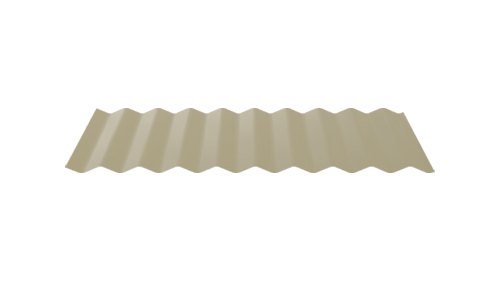

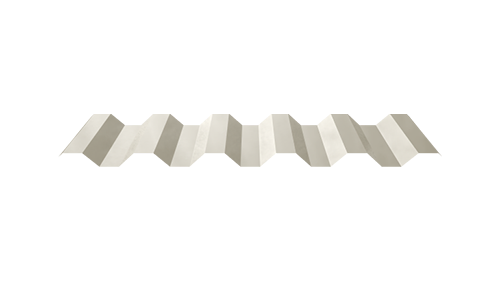

Sinewave 2.67” x 1/2″

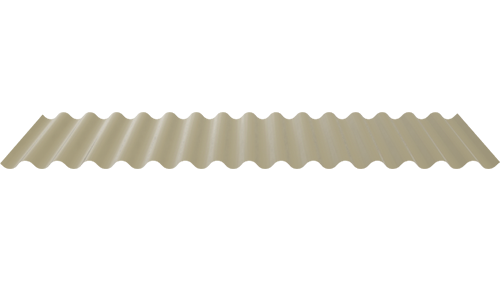

Sinewave 2.67” x 3/4″

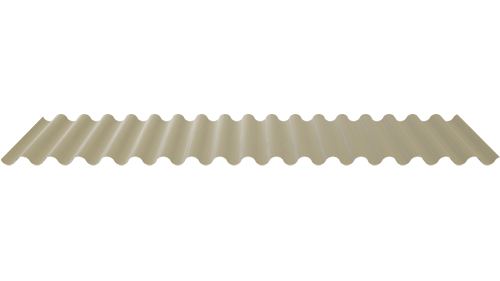

Sinewave 2.67” x 7/8″

These rounded profiles are incredibly versatile and known for their flexibility. They are especially well-suited for barrel roofs, curved facades, and applications where traditional corrugation enhances the design or provides needed adaptability. For example, the 2.67″ x 1/2″ profile is commonly used in agricultural sheds with curved roofs, while the deeper 7/8” version can offer added dimension for architectural accents.

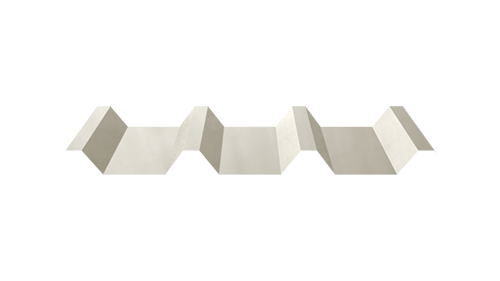

2. Box Ribs & Structural Profiles

Box beam panels dress up the facade of this building in Ballpark Commons.

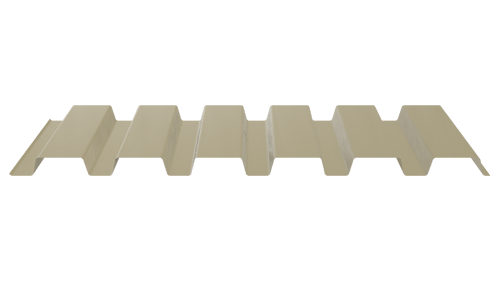

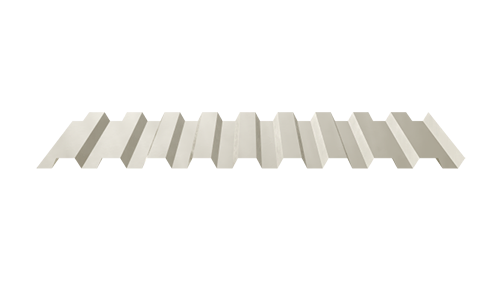

B-Deck

4” Rib

8” Rib

Box Beam

RS 7.2

Best for: Strong structural performance, bold appearances, and projects requiring strength under load.

These panels are designed to span greater distances and provide excellent load support, making them ideal for mezzanine decking, commercial roofing, and long, unsupported siding runs. For instance, B-Deck is a go-to for steel decking applications, while the RS 7.2 is often chosen for high-wind areas that require enhanced rigidity.

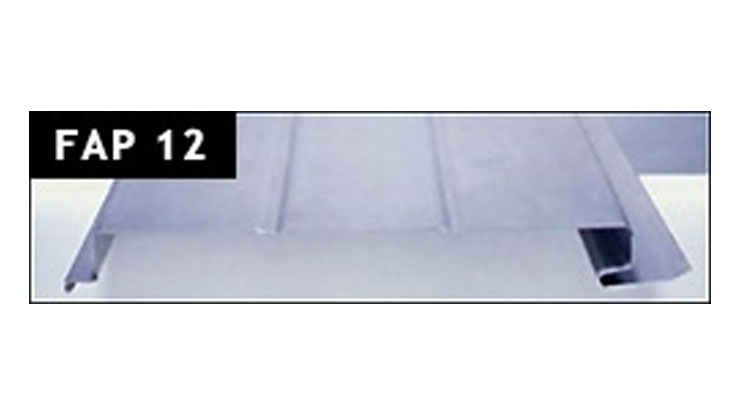

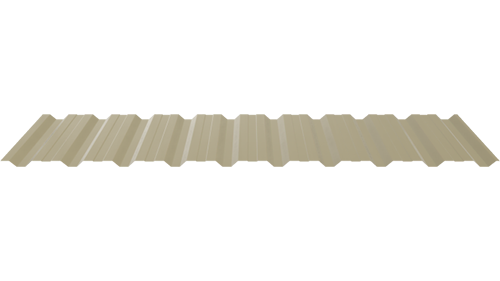

3. Architectural Panels

V-Beam

FAP 12

Bold Rib

Best for: High-visibility projects that require form and function.

Architectural profiles balance clean, striking lines with dependable performance. They bring rhythm and contrast to building exteriors and are frequently used in urban buildings, modern warehouses, and transportation hubs. The Bold Rib panel, for example, was featured in a museum facade where visual texture and durability were equally important.

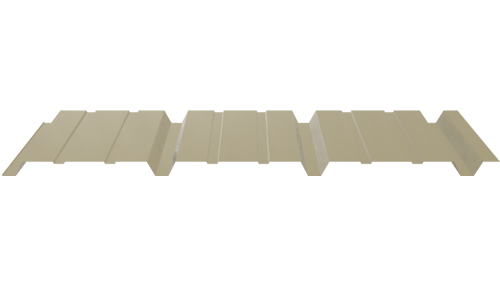

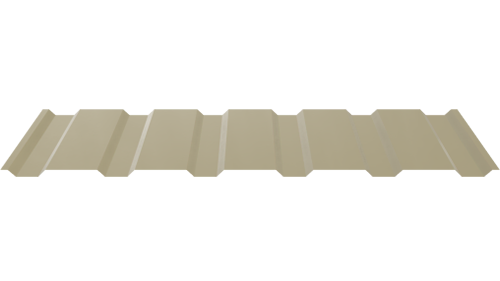

4. Agricultural Panels

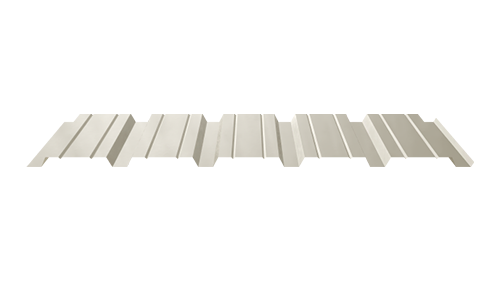

R-Panel

A-Panel

Best for: Barns, sheds, and utility buildings.

A staple in rural construction, these panels offer quick coverage, easy installation, and weather resistance. They’re ideal for livestock shelters, grain storage buildings, and any application where cost efficiency and function are top priorities. R-Panel, in particular, is widely used on equipment storage buildings and pole barns.

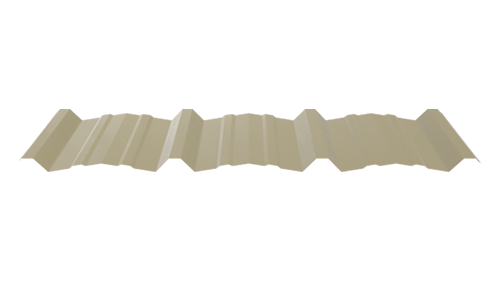

5. Specialty Panels

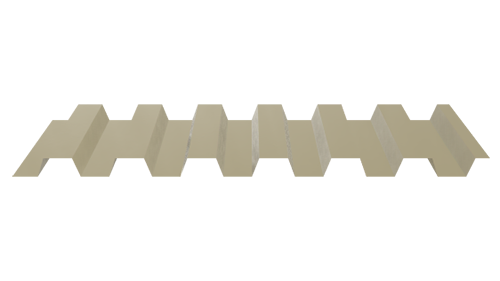

Harvest Panel

Trail Rib

Best for: Flooring and trailer applications in the transportation industry.

These heavy-duty panels are engineered for high-impact, high-friction environments. Harvest Panel and Trail Rib are most often used in trailer beds, truck flooring, and other surfaces where traction, drainage, and durability are essential. For example, Trail Rib is commonly specified by trailer manufacturers for flooring panels.

Choose with Confidence

With so many panel profiles to choose from, it’s easy to assume they’re all interchangeable, but the right choice can elevate your project’s performance and appearance. Choosing the right profile can make all the difference — visually, structurally, and financially.

Whether you need a durable, bold solution for an industrial structure, a sleek profile for architectural appeal, or a tried-and-true classic for curved roofing, CMI has the panel — and the expertise — to match.

Not sure which profile fits your application best? Our team is here to help you spec the right panel for your goals, your timeline, and your bottom line. Get in touch with us today.