About Corrugated Metals

We are proud to be a go-to partner to buyers, contractors, original equipment manufacturers, designers, and builders. Learn more about Corrugated Metals, Inc.

Corrugated Metals, Incorporated is a leading manufacturer of formed metal products. We serve the Construction, Original Equipment, Defense Industries, and others. Our affiliated company – Infrastructure Defense Technologies, LLC – engages in the marketing and sale of defense products, which are manufactured by CMI.

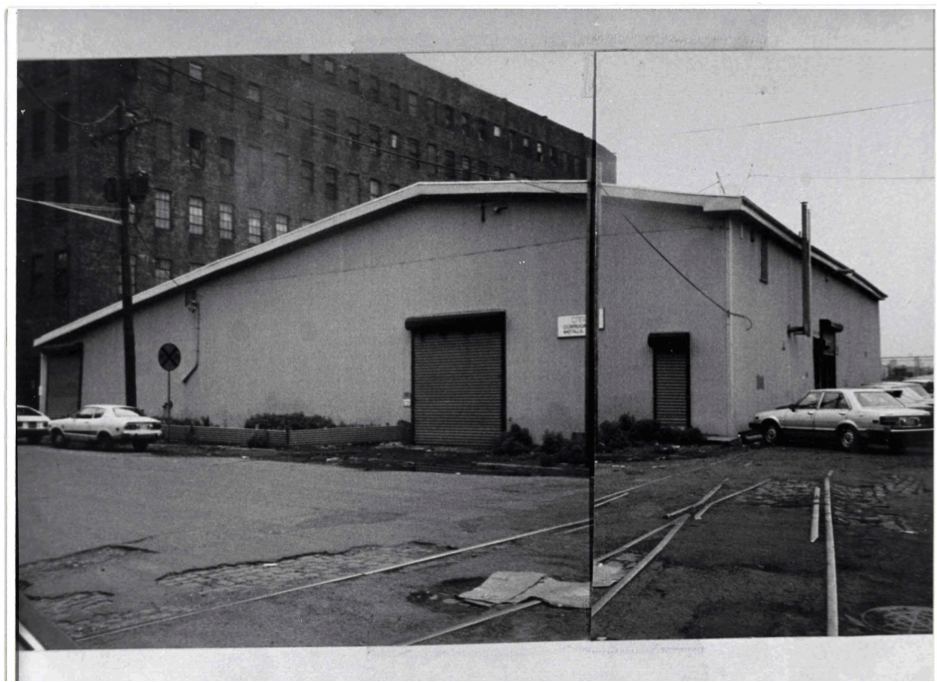

CMI was established in 1887 in Jersey City, New Jersey. But later relocated its operations to the Midwest in 1991. Today, the company operates from a single location in Belvidere, Illinois. Additionally, CMI sells its products throughout the United States, and internationally.

We use manufacturing processes such as custom roll forming, press-braking, mechanical power-press operations, shearing, cut-to-length and turret-punch operations. Our capabilities surpass those of our competitors, which allows CMI to deliver superior services and solutions.

Marketing Strategy

At CMI, we seek to develop long-term customer relationships in the markets we serve. We pursue three strategies to achieve this goal:

Develop/Introduce New Products

CMI aggressively develops new products which are typically driven by customer requirements.

Expand Capabilities

CMI regularly purchases equipment which provides new capabilities in support of new product development.

Enhance and Utilize Excess Capacity

CMI has abundant un-utilized capacity, which enables it to service customer requirements efficiently and effectively.

Commitment to Safety

CMI management and ownership places the highest priorities on safe practices in the plant.

Commitment to Quality

CMI and IDT are both ISO 9001: 2015 registered. CMI is also registered with the American Association of Railroads for quality. From time to time, the company is required to do work to Nuclear Quality Assurance Standards (NQA-1). This process requires audits prior to and during production, as well as archiving after shipment.

Our Mission

- Produce defect-free products, provide excellent service and competitive prices for our customers

- Pursue growth strategies to help us build the value of the business

- Employ rational, deliberate and well-reasoned decision making in every aspect of our business

- Utilize continuous improvement methodologies to maximize efficiency and minimize waste

- Treat our employees fairly in terms of compensation, benefits, professional and safe work environment, and clearly defined expectations

- Ensure safety, quality and efficiency in our production operations

- Be prepared – to the best of our abilities – to handle any challenge, planned or unplanned, elective or involuntary

- Maximize Profits

- Give thanks for our success with charitable acts